Vacuum Distillation

What We Do

Industry Use Case

- Chemical and Pharmaceutical industry

- Oil and Gas industry

- Food and Beverage industry

Proteus Multi-meter

What We Do

Industry Use Case

- Wastewater management

- Environmental Monitoring

- Agricultural Applications

- Potable Water Safety

- Industrial Monitoring

- Groundwater and Borehole Monitoring

- Management of Harmful Algal Blooms (HABs)

Filtration Technologies (MUNRO)

What We Do

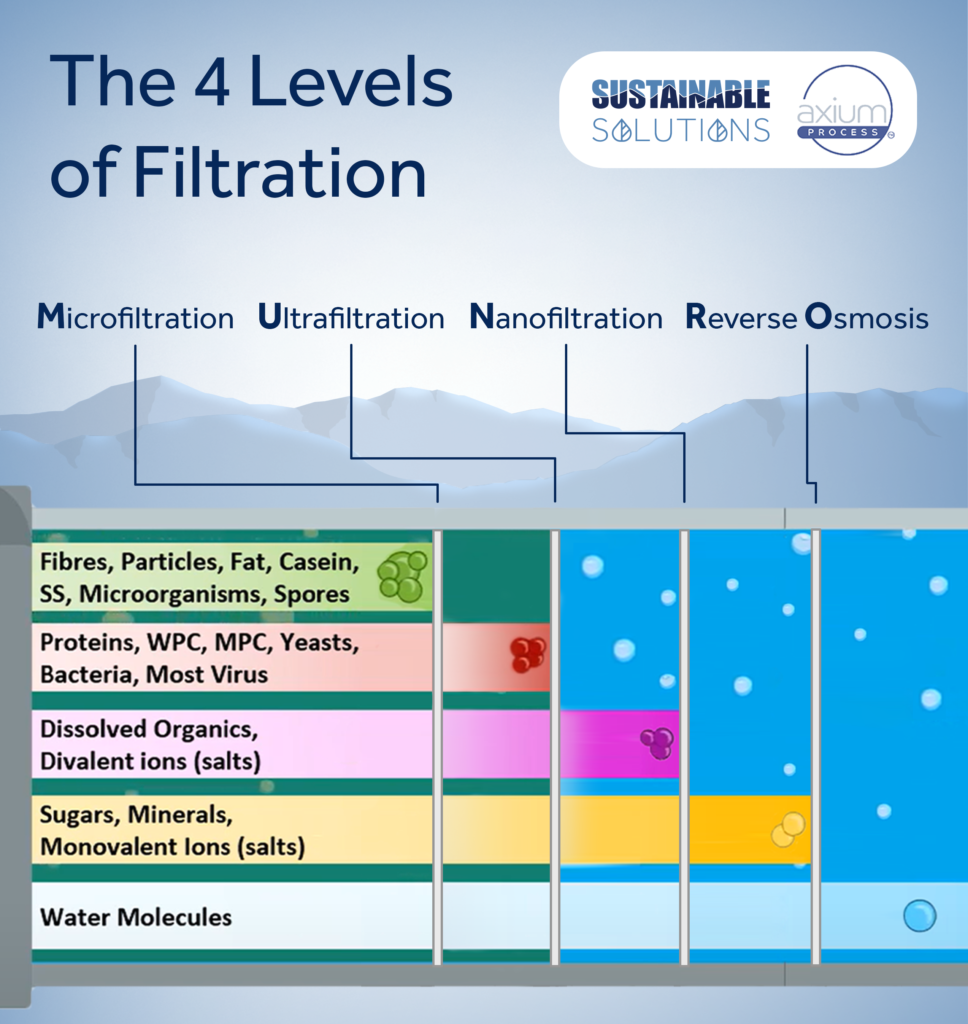

We have partnered with Axium Process which

specializes in crossflow membrane filtration

and separation technologies, which are utilised

extensively in the pharmaceutical, food and

beverage industries for liquid processing tasks

such as product separation, clarification,

purification, and water recovery. These

technologies include Microfiltration (M),

Ultrafiltration (U), Nanofiltration (N), and Reverse

Osmosis (RO).

Industry Use Case

- Chemical and Pharmaceutical industry

- Water Treatment Sector

- Food and Beverage industry

Solids Control Equipment

What We Do

Utilising advanced solids control equipment

for Pot Ale treatment directly from the still

ensures effective liquid-solid separation and

significant COD reduction. Key technologies

include shale shakers, decanter centrifuges,

and hydrocyclones, optimizing cleanliness and

efficiency in various industries. These methods

not only recycle and ready mud for reuse,

reducing costs and environmental impact, but

also enhance product quality through efficient

separation processes.

Industry Use Case

- Beverage Production

- Pharmaceutical industry

- Chemical Industry

- Oil and Gas

- Brewing Industry

- Waste Water Treatment

DAF (Dissolved Air Flotation)

What We Do

Industry Use Case

- Food and Beverage Beverage Industry

- Pharmaceutical industry

- Oil Refineries

- Aquaculture

CIP Systems

What We Do

Industry Use Case

- Pharmaceuticals

- Food, Dairy, and Beverage Industries

- Breweries and Distilleries

Nemesis Equipment

What We Do

Industry Use Case

- Oil & Gas Industry

- Energy Sector

- Drilling operations

- Maintenance and Cleaning

Client Field/Site Visits

What We Do

Industry Use Case

- Effluent Treatment

- Sludge Management

- Process Improvement

- Environmental Compliance

Onsite Laboratory Analysis

What We Do

Technical Report Writing

What We Do

Ready to discover more about Sustainable Solutions?

Don’t hesitate – reach out to us today to find the answers to your questions and connect with a team that’s shaping the future of the renewable energy sector. Take the first step towards a greener, more efficient future by getting in touch with us now. We’re excited to hear from you!